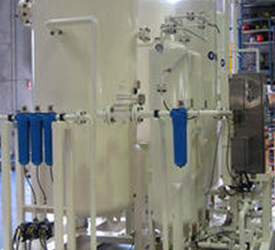

Pressure Swing Adsorption (PSA)

Oxair specialises in nitrogen Pressure Swing Adsorption (PSA) generators. PSA nitrogen generators offer high purity nitrogen while driving down costs with savings of up to 50% over traditional supply methods. PSA is widely applied at industrial facilities in a range of sectors, including marine, electronics, food and beverage, metal fabrication, pharmaceuticals, and oil and gas for the recovery of high-purity nitrogen.

Flow Rates

We supply Nitrogen Generators from 1 to 10,000 SM3/ of nitrogen per hour.

PSA technology produces inert gas at low pressure, removing the safety hazards associated with high pressure gas cylinders and bulk cryogenic liquefied gas. It works by allowing Oxygen molecules to diffuse into the pore structure of the adsorbent, while nitrogen molecules flow freely upwards to the top of the Adsorber vessel.

At the regeneration stage the adsorbed components are released into the atmosphere and the process is then repeated. Oxair’s standard models produce flow rates of pure nitrogen from the air of up to 99.9%. +

Why choose Oxair?

Our proven nitrogen PSA technology ensures reliable supplies of pure nitrogen. For greater flexibility, we will work closely with you to create tailor-made systems to suit any application.

Parts are built to last on our nitrogen generators, which are operator friendly, meaning minimal maintenance and labour interaction. On the smaller systems the process valves will last 6-8 years before maintenance. Whereas, on the larger systems, the actuators can withstand 4 million cycles before requiring maintenance. Our nitrogen generators are efficient and compact equipment making them ideal for establishments where space is limited.

Microprocessor controlled, allowing for unattended operation, noise levels are reduced thanks to a muffler design. Other advantages of our nitrogen generators are an economiser that shuts the system down during low demand, while the high cycle process valves provide exceptional reliability of supply.

Oxair design and build two large Nitrogen PSA systems ( 650 m3/hr each) for an Oil and Gas Refinery in Iraq

Oxair’s designs are focused on meeting exacting customer requirements, reliability, ease of maintenance, safety, and plant self-protection. We are a world leading manufacturer of gas process systems, for shipboard and land-based use to suit any requirement.

Features

• Proven Nitrogen PSA technology produces highly reliable nitrogen supply at your site

• Nitrogen purities from 95.0% to 99.99% for greatest flexibility and cost savings

• Simple engineering with few moving parts means minimal maintenance, maximum reliability

• Small footprint for compact installation

• Microprocessor – (PLC) control system allows unattended operation and maintains highest efficiency

• Low Noise levels. – Oxair Proprietary Low Noise Muffler Design

• Economiser shuts system down during low demand to increase savings

• High Cycle process valves provide high reliability with minimal maintenance

• Actuators with 4 million cycles before maintenance